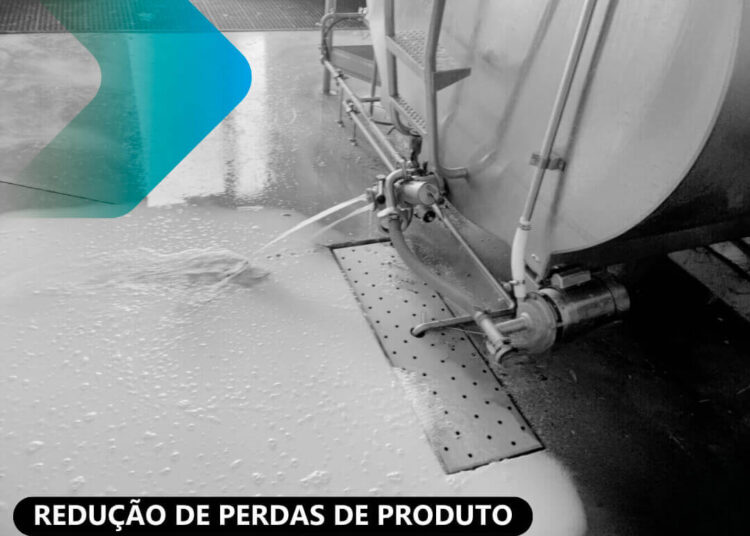

Reducing losses in industrial processes is a constant challenge. For example, in a milk unloading line, where the product is transferred to a tank or silo, there are critical moments at the beginning and end of the transfer. Initially, it is essential to drain the residual water from the last cleaning-in-place (CIP) rinse. At the end, it is necessary to bleed the line, which involves injecting water to push the product to its destination. This process is often performed manually or based on a timer, leading to significant product losses.

The solution proposed by PROCCIP enables the implementation of an advanced system to minimize these losses and optimize product recovery. This is achieved through the automation of header valves, which control the entry of bleed water and drainage. In conjunction, a turbidimeter is used, which can be combined with or replaced by a flow transmitter, depending on the specific needs of the application. This simplified automation allows precise monitoring of the water-product interface, reducing losses and increasing process safety.

This solution can be applied to any transfer line in your process that involves drainage and bleeding stages. It can also be implemented in equipment such as pasteurizers, for example.

In addition to being efficient, the designed solution offers a very fast return on investment (payback). Are you interested in learning more about how to implement this system in your plant and improve your process? Contact us for a detailed discussion about how we can assist you.

PROCCIP: First, the essentials.